Hose Training

Swagelok® Hose Essentials Training

Hoses are critical yet often overlooked components of fluid systems. Swagelok® Hose Essentials Training in Vietnam equips professionals with the knowledge and hands-on skills to select, install, and inspect hoses safely and effectively. This course helps organizations improve reliability, reduce failures, and extend hose service life across diverse applications.

Course Content

Participants will gain practical skills and technical knowledge, including:

- Hose vs traditional tube systems

- Typical considerations when determining hose use

- Hose life

- Discuss hose construction, include:

- The properties of the core

- The importance of reinforcement layers

- Hose covers

- The needs for hose identification

- Methods to attach end connections

- Proper hose storage

- Identify considerations for determining hose length and routing

- Flexibility and ovality

- STAMPED

- Proper hose installation techniques

- Hose inspection

- Practical activities

Course Outcome

Upon completion, participants will be able to:

- Define common hose terms and terminology

- Describe how to evaluate hose fit for purpose

- Describe hose selection variables

- Describe guidelines for hose installation

- Identify common issues in hose applications

Course Details

- Duration: 1 day

- Maximum Class Size: 15 attendees

- Prerequisite: None

- Assessment: Written and practical exams to validate knowledge and skills

- Certificate: Swagelok® Certificate of Completion (valid for 3 years upon successful exam completion)

Who Should Attend?

This training is designed for:

- Fabricators working with fluid system assemblies

- Contractors involved in hose installation projects

- Technicians handling hose operation and maintenance

- Engineers and draftsmen designing and specifying hose systems

- Quality control personnel verifying hose safety and performance

- Safety engineers responsible for minimizing operational risks

- Anyone who selects, purchases, installs, operates, or maintains hoses in industrial environments

Test Your Knowledge

Do you know the correct way to tighten a 1/4 inch tube fitting from finger-tight position on first installation?

Getting this step right is critical for safety and leak-free performance.

Location & Options

Training is available at our Swagelok Vietnam facility or can be hosted at your site upon request.

Swagelok Vietnam HCM head office: 532A Le Trong Tan Street, Tay Thanh Ward, Ho Chi Minh, Vietnam

Questions or Custom Training?

Interested in hosting a training session at your facility or customizing content for your team?

Call us at 0936 42 0804 (available via Zalo) or email to van.nguyen@swagelok.com.vn

Other Available Courses:

- Tube Fitting Installation Essentials

- Tube Bending Essentials

- Tube Fitting Inspection Essentials

- Medium- and High-Pressure Cone and Thread Essentials

- VCR® and VCO® Fitting Essentials

- FK Fitting Essentials

- Process Analyzer Sampling System Class

- M200 Orbital Welding Class

Swagelok Tube Fitter’s Manual

Learn how to install compression fittings onto small-bore industrial tubing in this comprehensive manual.

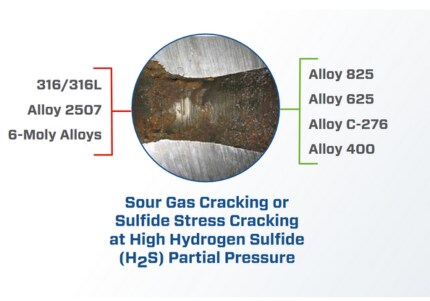

Materials Selection Guide

Discover the factors that contribute to corrosion and other materials-related challenges and specify materials that will last in your applications.

View more Swagelok Training blogs

Explore our list of blog articles focused on the benefits of fluid system and sampling system training, common best practices, and basic design principles.