Corrosion Resistant Metals

Understand the materials available to help control the many types of corrosion.

> View and download a print-friendly version of the Materials Selection Guide

316 Stainless Steel

Stainless Steel

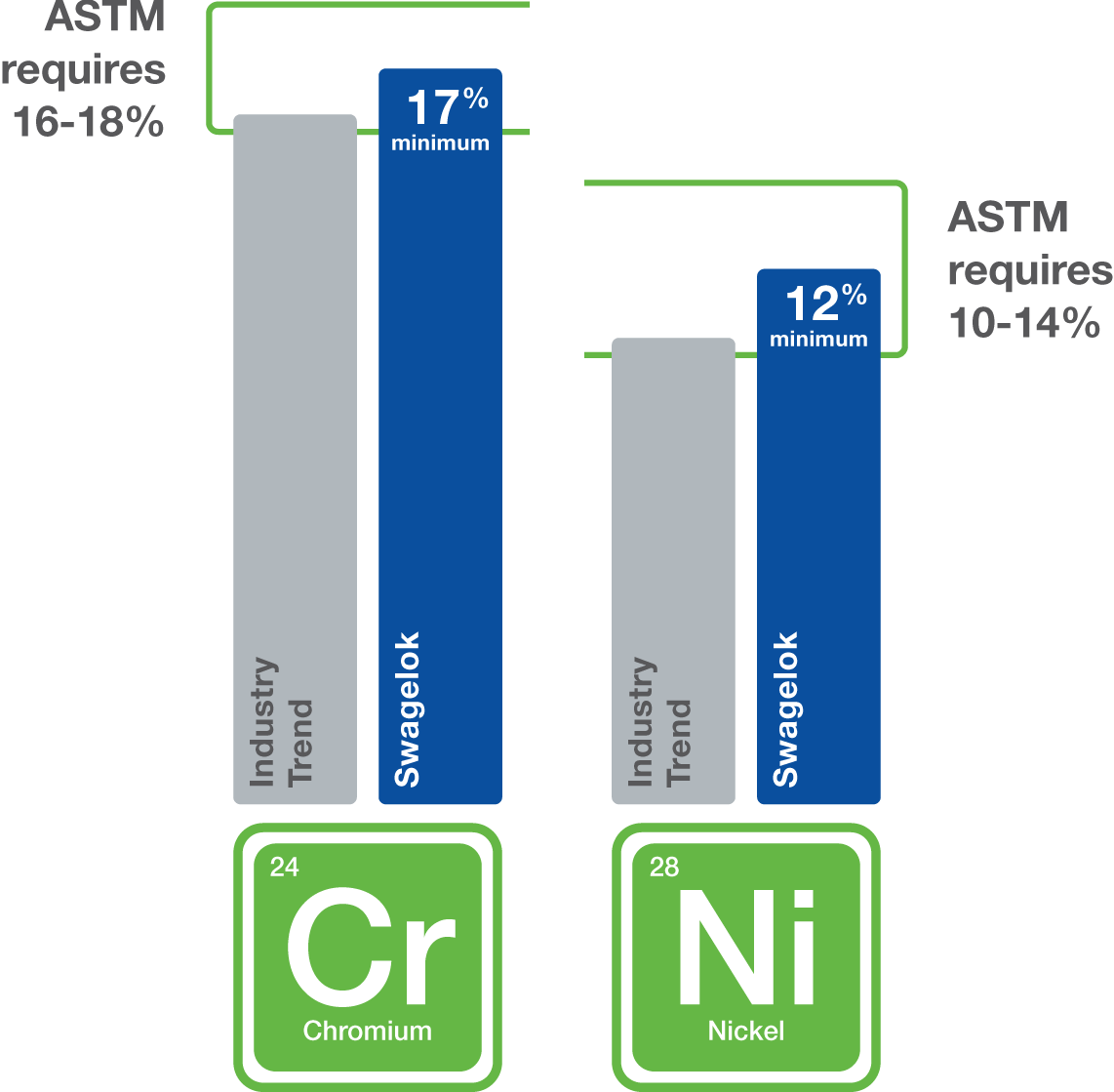

In all stainless steels, chromium and nickel are critical for corrosion resistance and ductility. The addition of >10% chromium transforms steel into stainless steel, creating an adherent and invisible oxide layer that is chromium-rich. This oxide layer forms when chromium in the alloy reacts with oxygen in ambient air. This layer gives steel its stainless character. The addition of nickel provides good ductility and ease of forming and welding.

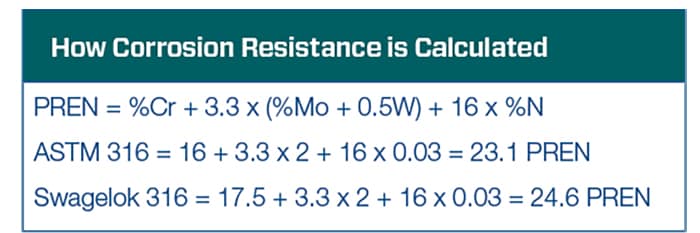

But not all bar stock is the same. Swagelok 316/316L stainless steel tube fittings and instrumentation valves contain more nickel and chromium than minimally required by ASTM standards for bars and forgings.

Note that although stainless steels will not suffer from general corrosion, they can be affected by localized corrosion.

For Fighting:

General Corrosion; Hydrogen Embrittlement; Intergranular Corrosion;

Material Matters

The risk of stress corrosion cracking (SCC) increases when chloride concentrations, temperatures, and tensile stress are high. No stainless steel is completely immune to SCC. We have performed SCC testing on pressurized Swagelok tube fittings with exceptional results.

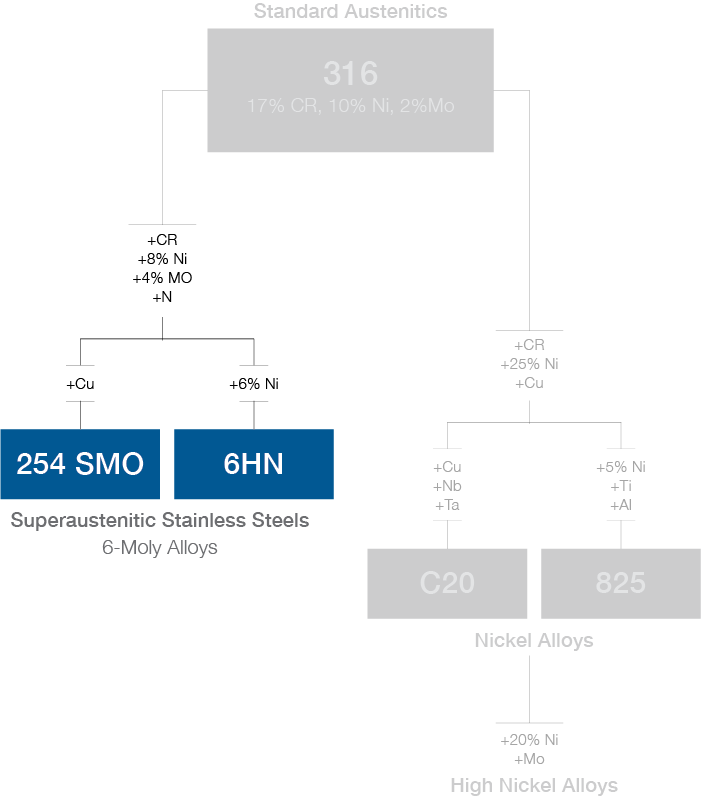

6-Moly Alloys

Stainless Steel

6-Moly (6Mo) alloys are superaustenitic stainless steels which contain at least 6% molybdenum and have a PREN of at least 40. Alloy 6HN (UNS N08367) contains 6 weight percent more nickel (Ni) than alloy 254 (UNS S31254). This increase in nickel content gives 6HN added stability with respect to formation of undesirable intermetallic phases. Alloy 6HN has been found to have better corrosion resistance in chloride-containing media than alloy 254.

- Resistance to chloride pitting and crevice corrosion

- Resistance to chloride stress corrosion cracking (CSCC)

- Material yield strength 50% greater than 300-series austenitic stainless steels

- Impact toughness, workability, and weldability

- Suitability for sour gas applications (NACE MR0175/ISO 15156)

- Swagelok 6-Moly products are available from 6HN (UNS N08367) bar stock and forgings qualified to the requirements of the NORSOK M-650 supply chain qualification standard.

For Fighting:

General Corrosion; Localized Corrosion; Stress Corrosion Cracking

Alloy 2507 Super Duplex Stainless Steel

Stainless Steel

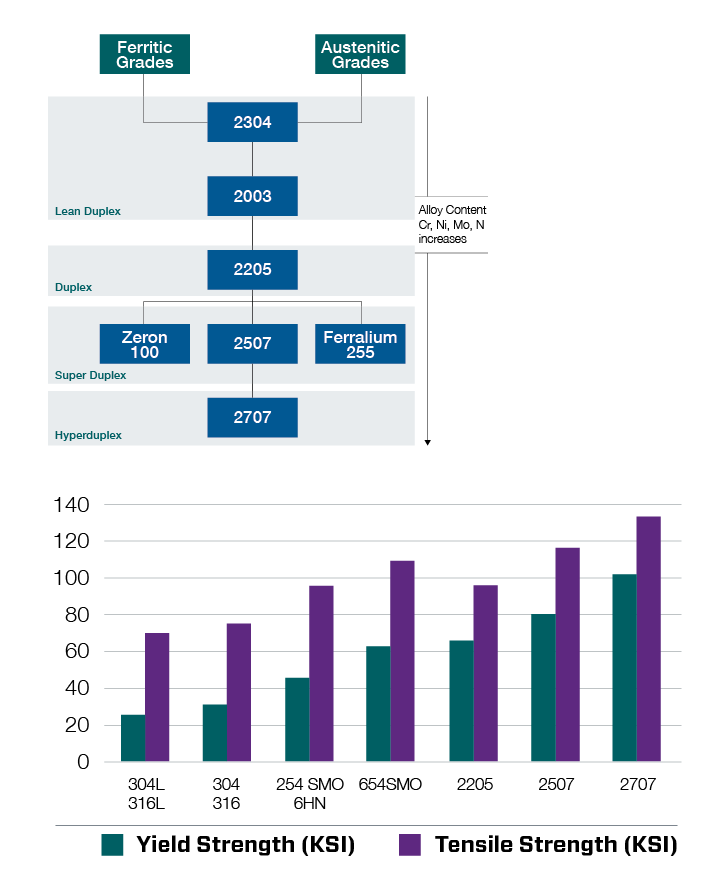

Duplex stainless steels have a two-phase microstructure of austenite and ferrite grains. This structure gives these materials a combination of attractive properties, including strength, ductility, and corrosion resistance.

Alloy 2507 super duplex, ferritic-austenitic stainless steel is well-suited for service in highly corrosive conditions. Its composition includes nickel, molybdenum, chromium, nitrogen, and manganese, offering excellent resistance to general corrosion, pitting, and crevice corrosion, and stress corrosion cracking (SCC), while maintaining weldability.

- Higher yield and tensile strength for increased pressure ratings

- Compared to 316/316L tubing of same outside diameter and pressure rating, lower wall thickness allows for increased flow of fluids

- Weldability

- Applications up to 482°F (250°C)

- Higher thermal conductivity/lower coefficient of thermal expansion than 316SS

- Suitability for sour gas applications (NACE MR0175/ISO 15156)

- Swagelok 2507 products are available from bar stock and forgings qualified to the requirements of the NORSOK M-650 supply chain qualification standard

For Fighting:

General Corrosion; Localized Corrosion; Stress Corrosion Cracking

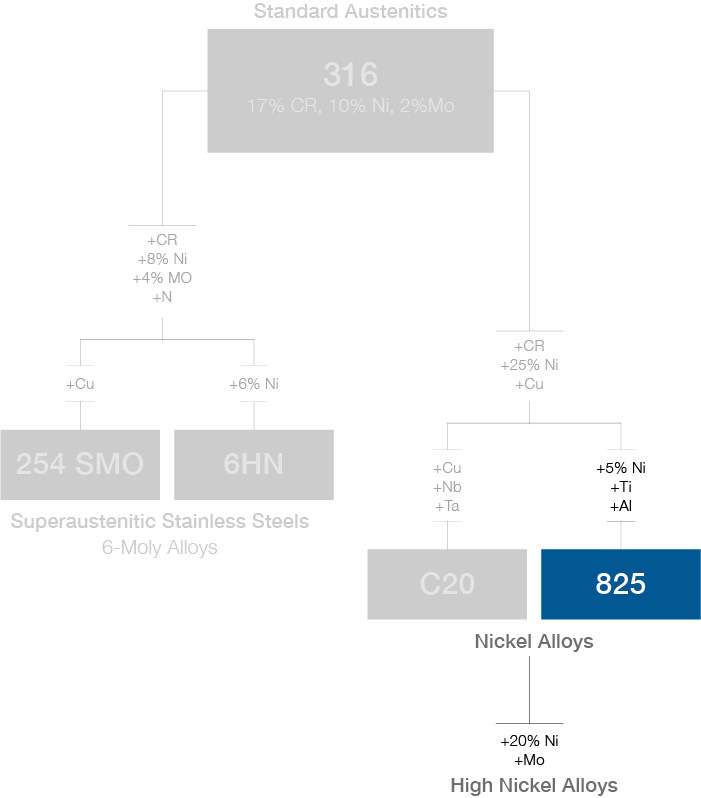

Alloy 825

Nickel Alloys

Alloy 825 (Incoloy® 825) is a nickel-iron-chromium-molybdenum alloy designed to resist general corrosion, pitting, and crevice corrosion, as well as stress corrosion cracking (SCC), in a wide range of media.

- Resistance to intergranular corrosion due to being stabilized with titanium

- Suitability for sour gas applications (NACE MR0175/ISO 15156)

- Resistance in reducing environments (i.e., sulfuric or phosphoric acid)

For Fighting:

General Corrosion; Localized Corrosion; Stress Corrosion Cracking; Sour Gas Cracking

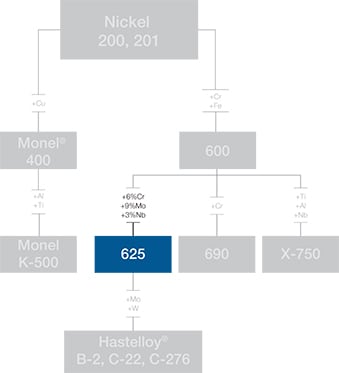

Alloy 625

Nickel Alloys

Alloy 625 (Inconel® 625) is a nickel-chromium-molybdenum alloy with a small quantity of niobium to reduce the risk of intergranular corrosion in a wide variety of severely corrosive environments.

- Resistance to hydrochloric and nitric acids

- Strength and ductility

- Resistance to crevice and pitting corrosion in high-temperature use

- Suitability for sour gas applications (NACE MR0175/ISO 15156)

Material Matters

For more information, see Alloy 625 Tube, Medium-Pressure, Pipe, and Weld Fittings NACE MR0175 Table A.13 Compliant.

For Fighting:

General Corrosion; Localized Corrosion; Stress Corrosion Cracking; Sour Gas Cracking

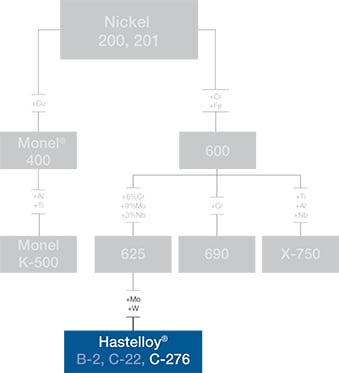

Alloy C-276

Nickel Alloys

Alloy C-276 (Hastelloy® C-276) contains nickel, molybdenum, and chromium. Its high molybdenum content makes it exceptionally resistant to pitting and crevice corrosion, and it is one of only a few materials that can withstand the corrosive effects of wet chlorine gas, hypochlorite, and chlorine dioxide.

- Resistance to oxidizing and reducing media

- Ductility, toughness, and strength at high temperatures

- Resistance to crevice and pitting corrosion, sulfide stress cracking, and intergranular corrosion

- Suitability for sour gas applications (NACE MR0175/ISO 15156)

Note that this alloy is NOT recommended with highly oxidizing environments, such as hot and concentrated nitric acid.

For Fighting:

General Corrosion; Localized Corrosion; Stress Corrosion Cracking; Sour Gas Cracking

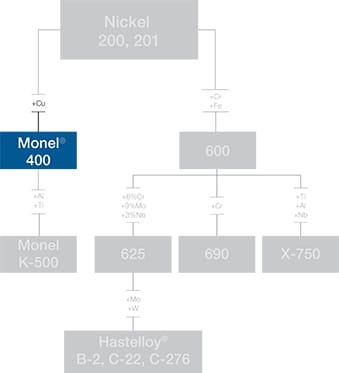

Alloy 400

Nickel Alloys

Alloy 400 (Monel® 400) is a nickel-copper alloy known for its exceptional resistance to hydrofluoric acid, as well as resistance to stress corrosion cracking and pitting in most fresh and industrial waters.

- Strength and corrosion resistance in a wide range of temperatures and media

- Mechanical properties retained at subzero temperatures

Note that stagnant seawater has been shown to induce crevice and pitting corrosion in this alloy.

For Fighting:

General Corrosion; Localized Corrosion; Stress Corrosion Cracking; Sour Gas Cracking

Titanium Alloys

A stable, strongly adherent oxide film protects titanium alloys from corrosion. This film forms instantly when a fresh surface is exposed to air or moisture. Anhydrous conditions in the absence of a source of oxygen should be avoided since the protective film may not be regenerated if damaged.

Titanium has been used successfully in many applications because of its excellent corrosion resistance in:

- Chloride-containing solutions and moist chlorine gas

- Aqueous solutions of chlorites, hypochlorites, perchlorates, and chlorine dioxide

- Natural and chlorinated seawater to relatively high temperatures

Titanium and its alloys:

- Have exceptionally high resistance to microbiologically induced corrosion (MIC)

- Are highly resistant to oxidizing acids over a wide range of concentrations and temperatures. Common acids in this category include nitric, chromic, perchloric, and hypochlorous (wet Cl2) acids.

Limiting factors for the application of titanium and its alloys include the following:

- Unalloyed titanium will sometimes corrode in aqueous chloride environments under conditions not predicted by general corrosion rates

- Dry chlorine can cause a rapid attack on titanium and may even cause ignition

- Titanium is unsuitable for use with fluorine gas, pure oxygen, or hydrogen

Engineered Combinations

In marine installations where Swagelok 316/316L stainless steel fittings have performed well, but 316/316L tubing has experienced crevice corrosion in tube clamps, it may be cost-effective to use 316/316L fittings in combination with tubing from a more corrosion-resistant alloy. Engineered combinations use Swagelok 316/316L tube fittings with tubing from alloys 254, 904L, 825, or Tungum® (copper alloy UNS C69100) tubing.

Elevated chromium and nickel levels in 316/316L provide Swagelok tube fittings with higher resistance to localized corrosion. Superior tube grip is achieved with Swagelok’s patented hinging-colleting™ back ferrule design that translates axial motion into radial swaging action on the tube, yet operates with a low assembly torque requirement. Swagelok’s patented SAT12 low-temperature carburization process is used to case-harden the surface of the back ferrules, which facilitates achieving excellent tube grip on tubing from the above alloys.

Engineered combinations can be a cost-efficient, corrosion-resistant solution that provides these advantages for installations in marine environments:

- Higher nickel and chromium contents in Swagelok standard 316 stainless steel than minimally required by ASTM A479, resulting in a higher PREN value and higher resistance to localized corrosion

- High resistance to pitting and crevice corrosion of special alloy tubing

- Low risk of galvanic corrosion based on positions of 316, 254, 904L, and 825 in galvanic chart, or based on long-term successful use of 316/316L fittings with Tungum tubing.

As with any mixed-material assembly, pressure ratings for tubing and fittings from different alloys are governed by the lower material rating. For pressure ratings, see Tubing Data – Engineered Combinations MS-06-117.

Pitting Resistance Equivalent Number (PREN) is the measurement of resistance to localized pitting corrosion. Higher PREN values indicate greater pitting corrosion resistance.

For more information, check out these additional helpful reference materials from Swagelok.

> View and download a print-friendly version of the Materials Selection Guide